When choosing a fully automatic copper aluminum bar bending machine, multiple aspects need to be considered to ensure that you select the equipment that best suits your needs. Here are some key steps and suggestions:

1、 Clear requirements:

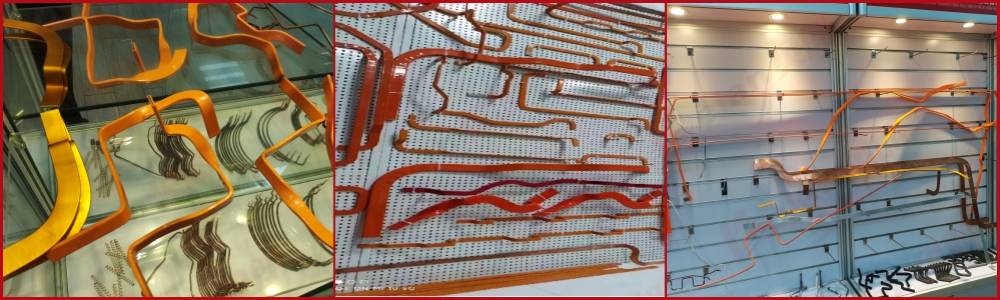

Firstly, clarify your copper aluminum bar processing requirements, including the type of processing material (such as copper, aluminum, etc.), specifications and dimensions, as well as the required processing accuracy and efficiency.

2. Consider your production scale and determine the required equipment capacity and processing speed.

2、 Research brand and model:

1. To understand the brands and models of fully automatic copper aluminum bar bending machines in the market, information can be obtained through industry exhibitions, professional websites, forums, and other channels.

2. Refer to the brand ranking and user reviews of the fully automatic copper aluminum bending machine, and choose a brand with good reputation and stable quality.

3、 Assess equipment performance:

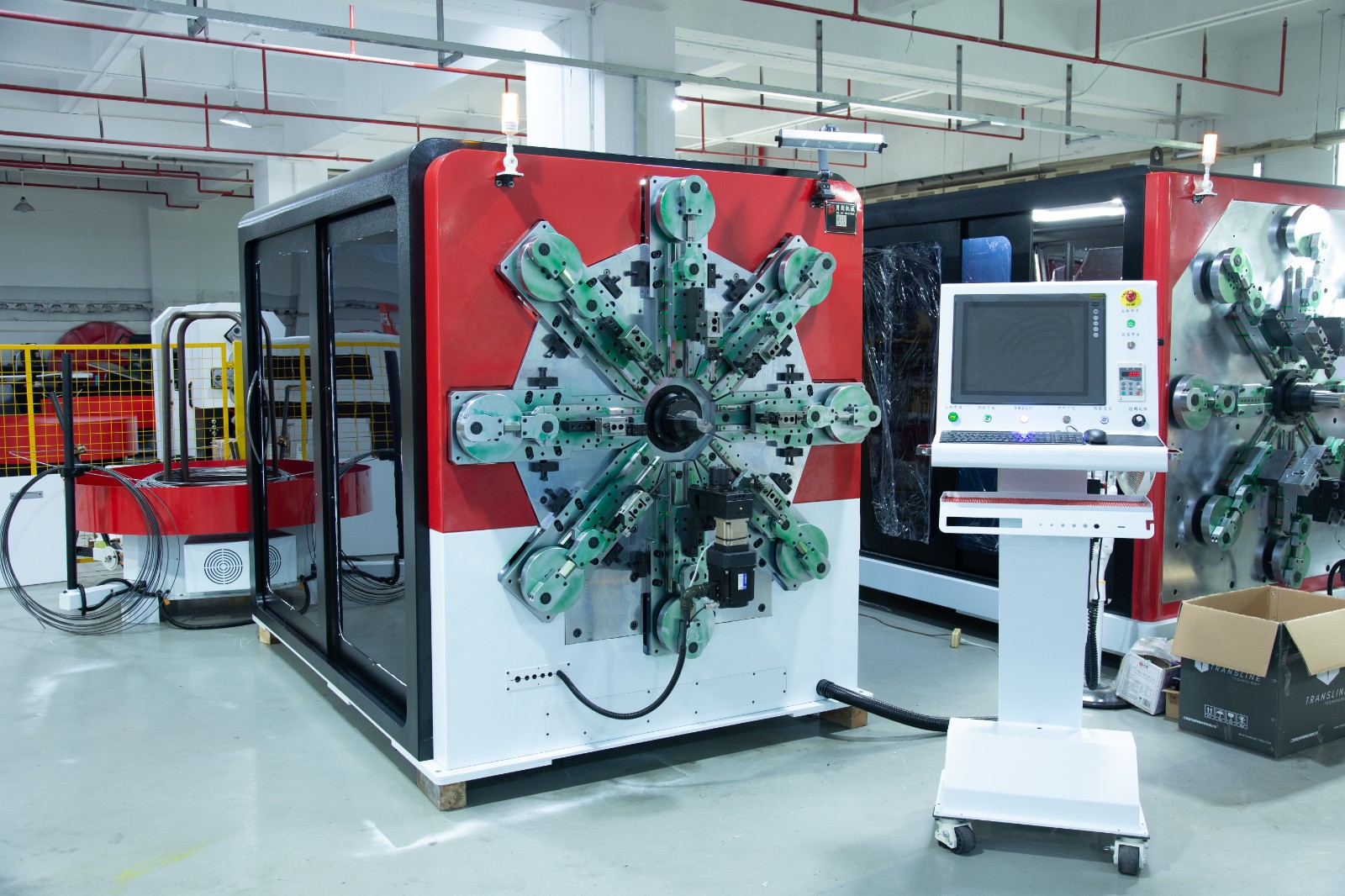

1. Investigate the machining accuracy, stability, and reliability of the equipment, which are related to product quality and production efficiency.

2. Pay attention to the automation level of the equipment, including functions such as automatic feeding, automatic positioning, and automatic detection, which can help improve production efficiency and reduce labor costs.

4、 Consider equipment quality:

1. Understand the material, process, and durability of the equipment, and choose durable and wear-resistant components and materials.

2. Inquire about the warranty period and after-sales service policy of the device to ensure timely technical support and maintenance services during use.

5、 Consider price factors:

1. Compare the prices of different brands and models of fully automatic copper aluminum bar bending machines, and conduct a comprehensive evaluation based on equipment performance and quality.

2. Be careful to avoid pursuing low prices while neglecting equipment performance and quality, and ensure that you purchase equipment with high cost-effectiveness.

6、 On site inspection and machine testing:

If conditions permit, on-site inspections can be conducted at equipment manufacturers or distributors to understand the actual operation and processing effects of the equipment.

2. Try operating the device and experience its convenience and user-friendly design.

7、 Sign contract and purchase:

After determining the purchase intention, sign a purchase contract with the equipment manufacturer or distributor, specifying the equipment specifications, price, delivery time, and other terms.

2. Ensure that the contract terms are clear and complete to avoid subsequent disputes.

Through the above steps, you should be able to purchase a fully automatic copper aluminum bar bending machine that suits your needs. During use, pay attention to regular maintenance and upkeep of the equipment to ensure its long-term stable operation.